I-Automated Storage and Retrieval Systems injalo nje - amasistimu azenzakalelayo agcina kahle futhi ngokuvikelekile izinto endaweni ehlangene.Ziphinde zivumele abasebenzisi ukuthi bathole kalula futhi ngokushesha izinto lapho kudingeka.Izinkampani eziningana zenza izinhlobo eziningi zokuziqukatha, izimpahla kuya komuntu, ukugcinwa okuzenzakalelayo kanye nezinhlelo zokubuyisa (ASRS).

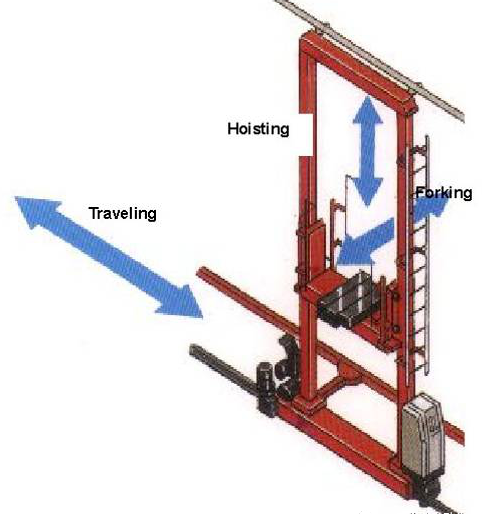

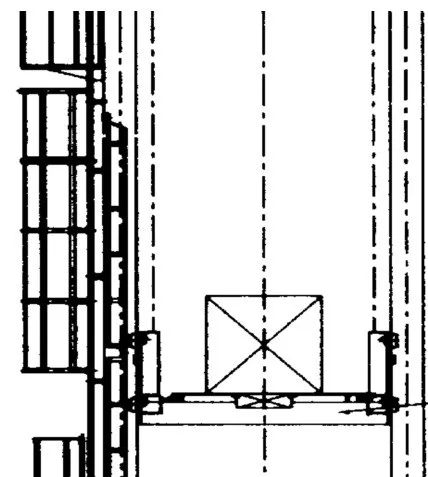

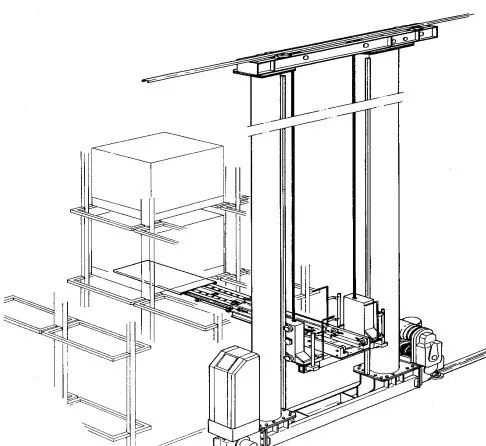

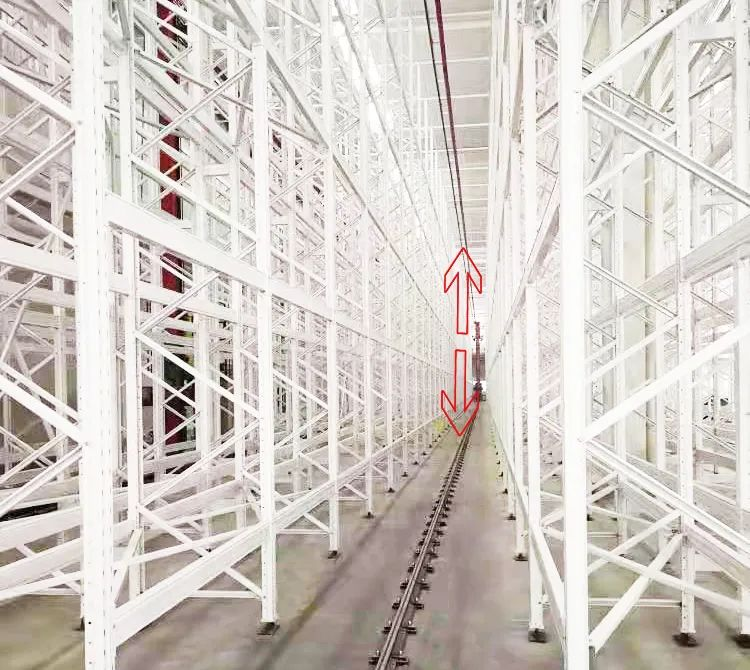

Isitaki, esaziwa nangokuthi i-crane yokupakisha, singagijima siye emuva naphambili ephasejini lendlu yokugcina impahla enezinhlangothi ezintathu, futhi sigcine izimpahla emnyango wephaseji endaweni yeshalofu emisiwe.Isitaki siyisisetshenziswa esiyisakhiwo sodumo sendawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo, futhi iyisisetshenziswa esibalulekile sokuphakamisa nezokuthutha endaweni yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo.

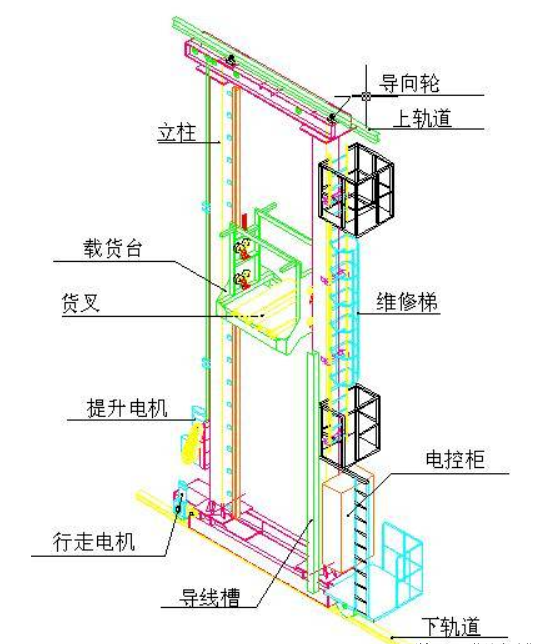

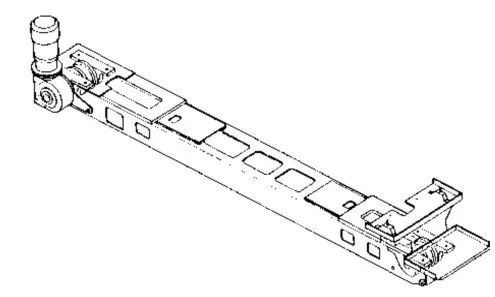

STACKER BASEumthwalo oguquguqukayo kanye nomthwalo omile owenziwe ngesikhathi sokusebenza kwe-stacker kudluliselwa kusuka ku-chassis kuya kumasondo ahambayo, ngakho-ke i-chassis yenziwe ngensimbi esindayo njengoba umzimba oyinhloko ushiselwe noma uboshwe ukuze ugcine ukuqina okuhle.

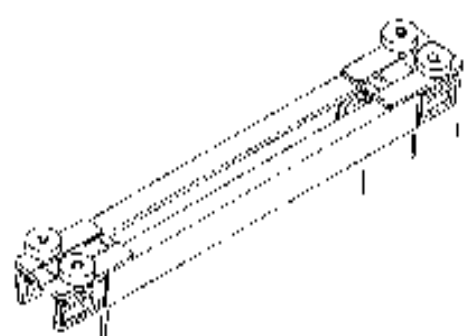

UMSHINI WOKUHAMBAUmshini wokugijima ubizwa nangokuthi i-horizontal running mechanism, eyakhiwe idivayisi yokushayela amandla, amasethi amasondo asebenzayo kanye ne-passive, kanye namabhafa asebenzayo.Isetshenziselwa ukusebenza kwayo yonke imishini ekuqondeni komgwaqo.

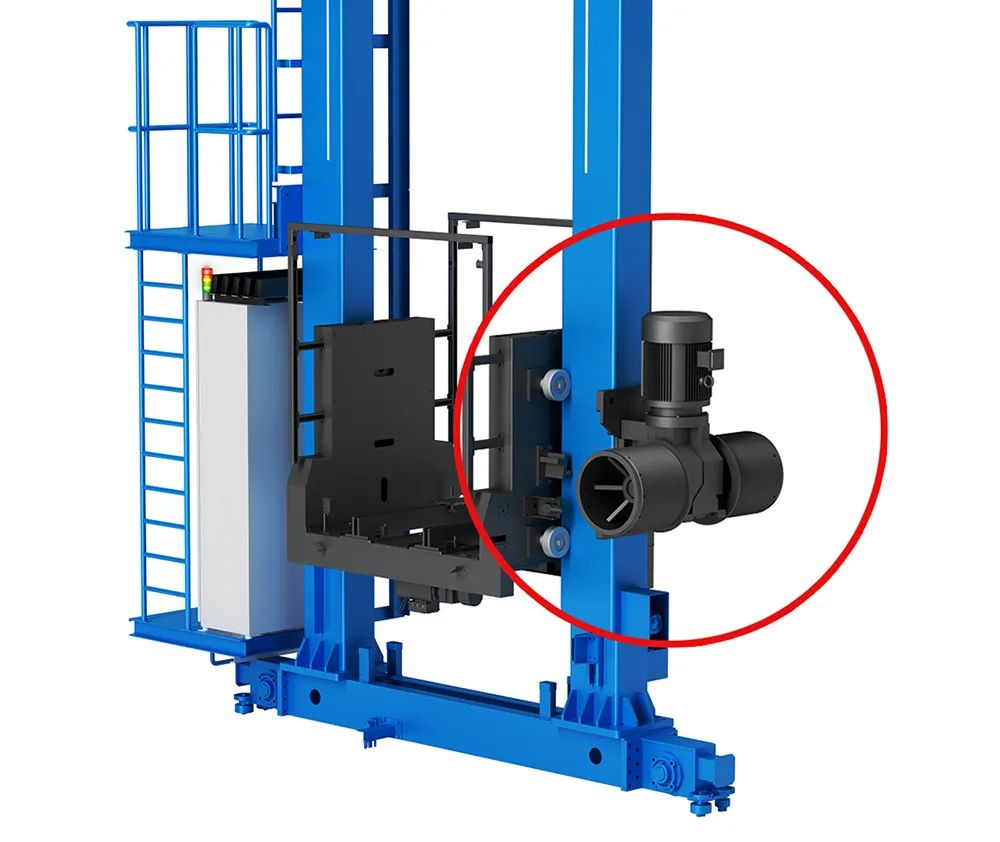

UMSHINI WOKUPHAKAMISAUmshini wokuphakamisa we-stacker ubizwa nangokuthi umshini wokuphakamisa, owakhiwe injini yokushayela, i-reel, iqembu elislayidayo, intambo yocingo, njll., futhi isetshenziselwa ukushayela isiteji sempahla ukuze sikhuphuke futhi siwe.Ukwakheka okuhlangene nokusebenza okuthembekile.

STACKER POSTIsitaki siwuhlobo lwe-double-mast, kodwa ukwakheka kwayo kwensika kusekelwe esilinganisweni samandla nesisindo esiphezulu (High Strength-to-Weight Ratio) ukwehlisa isikhungo sokudonsela phansi ukuze kugcinwe ukusebenza okuzinzile;Amasondo omhlahlandlela oseceleni, ukusekela kanye nokuqondisa ngakujantshi ongaphezulu lapho uhamba;iladi lokuphepha elihlomele ukuhlinzeka ngokulungiswa.

I-Beam ephezuluI-beam engenhla ingaphezulu kwekholomu ephindwe kabili, kanye ne-beam engezansi futhi ikholomu ephindwe kabili yakha isakhiwo sefreyimu esizinzile, isondo elingenhla eliqondisayo lingavimbela isitaki ukuthi singasuki emzileni ongaphezulu.

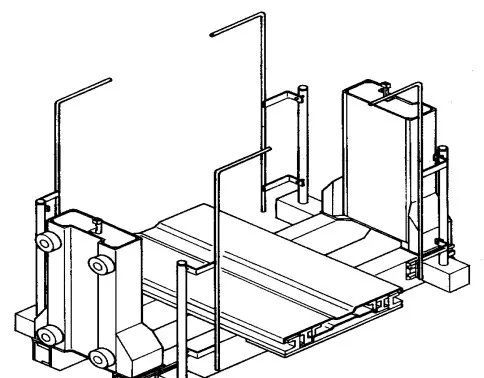

Ilayisha i-Lift PlatformIsiteji sokulayisha siyingxenye ye-stacker eyamukela izimpahla futhi yenza ukunyakaza kokuphakamisa.Itholakala maphakathi namakholomu akabili, injini ephakamisayo ishayela inkundla yezimpahla ukuthi iye phezulu naphansi.Iplathifomu yokulayisha ayifakelwe nje kuphela izinto zokuhlonza imithwalo yobude obungaphezu kobude, ububanzi obudlulele, kanye nobude obungaphezu kobude, kodwa futhi nezithonjana zangempela zokuma kwempahla ukuze kuvinjelwe ukungabekezelelani noma ukugcinwa kabili kwezimpahla.

ImfolokoI-fork telescopic mechanism iwumshini owenziwe ngamandla okushayela kanye nama-trident aphezulu, aphakathi nendawo naphansi, asetshenziselwa ukuhanjiswa kwezimpahla ngendlela eqonde ngqo endleleni yomgwaqo.Imfoloko engezansi igxilile endaweni yokulayisha, futhi izimfoloko ezintathu zinwetshwa ngendlela eqondile futhi zihoxiswa ngokudluliselwa kwamaketango.

I-Top Guide Rail&Bottom Guide Railumzila oqondisayo ohlangothini olungaphezulu nohlangothi olungezansi ukuze wenze i-stacker crane ukuhamba eduze kwamareyili aqondisayo.

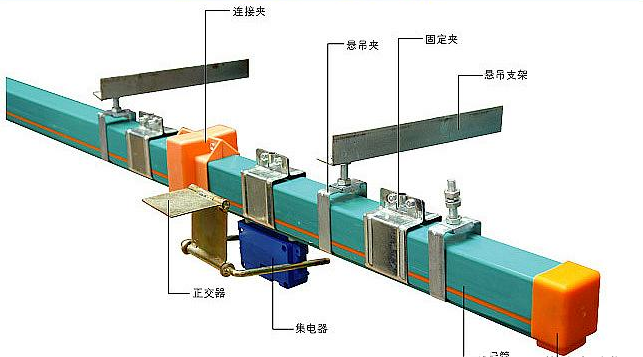

Umzila Wesitimela WamandlaItholakala engxenyeni engezansi yeshalofu ku-aisle ye-stacker, inikeza amandla okusebenza kwesitaki.Ukuze uvikeleke, ulayini wokuxhumana oshelelayo we-tubula ngokuvamile usetshenziswa.

Iphaneli yokulawulaKufakwe ku-stacker, i-PLC eyakhelwe ngaphakathi, isiguquli sefrikhwensi, ukunikezwa kwamandla kagesi, ukushintshwa kwe-electromagnetic nezinye izinto.Iphaneli ephezulu iwukusebenza kwesikrini esithintwayo, esingena esikhundleni sezinkinobho zokuqala zokusebenza, okhiye, namaswishi okukhetha.Kukhona indawo yokuma ngqo phambi kwephaneli yokulawula, elungele ukulungisa iphutha le-stacker.

Isikhathi sokuthumela: Feb-08-2023