Isitoreji Esizenzakalelayo Nohlelo Lokuhlola Kabusha

-

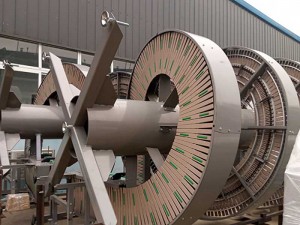

I-cladding rack isekelwe uhlelo lwe-ASRS

I-ASRS imfushane ngesitoreji esizenzakalelayo kanye nesistimu yokubuyisa. Ibizwa nangokuthi i-Stacker Crane Racking system ewuhlelo olusebenzayo nolusebenza ngokuzenzakalelayo lokugcina kanye nohlelo lokubuyisa. Ngama-aisles amancane nobude obungaphezu kwamamitha angu-30, lesi sixazululo sinikeza isitoreji esisebenza kahle, esiphezulu sokuminyana kwezinhlobonhlobo ezinkulu zamaphalethi.

-

I-ASRS Automated Storage and Retrieval System Rack

Isitoreji esizenzakalelayo nezinhlelo zokubuyisa zihlale zaziwa njengezinhlelo ze-AS/RS noma ze-ASRS. Isistimu yokugcina okuzenzakalelayo ehlanganisa isofthiwe elawulwayo, amakhompuyutha, nama-stacker cranes, okokusebenza, isistimu yokuthutha, isistimu yokugcina, i-WMS/WCS kanye nesistimu yokubuyisela endaweni yokugcina impahla. Isebenzisa ngokugcwele umhlaba olinganiselwe, uhlelo lwe-ASRS lukhulisa ukusetshenziswa kwendawo njengenjongo eyinhloko.Izinga lokusetshenziswa kwesistimu ye-ASRS izikhathi ezingu-2-5 zezindawo zokugcina izimpahla ezivamile.

-

Umthwalo Omncane AS/RS | Isitoreji Esizenzakalelayo Nohlelo Lokuthola

I-Automated Storage & Retrieval system iphatha kahle i-warehouse yakho ngokugcwele

isitoreji kanye ne-intra logistics. Okukhiphayo okuphezulu okunabasebenzi abaphansi kakhulu. Ukusetshenziswa okungcono kakhulu kwesikhala esiqondile.

Ubuningi bokuphepha komsebenzisi futhi kuthobela ngisho nezimiso zokuphepha eziqinile. Uhlelo luthembisa ikhwalithi Ethuthukisiwe nokuvumelana.

-

Ukulayisha okuncane kwe-ASRS okuzenzakalelayo kwezingxenye ezincane zokugcina impahla

Ukulayisha okuncane kwe-ASRS okuzenzakalelayo kwezingxenye ezincane zesitoreji kukwenza ugcine izimpahla ezitsheni nasemabhokisini ngokushesha, kalula nangokuthembekile. I-Miniload ASRS inikeza izikhathi ezimfishane zokufinyelela, ukusetshenziswa kwendawo okuphelele, ukusebenza okuphezulu kokuphatha kanye nokufinyelela okuphelele ezingxenyeni ezincane. Ukulayisha okuncane okuzenzakalelayo kwe-ASRS kungenziwa ngaphansi kwamazinga okushisa avamile, isitoreji esibandayo kanye nendawo yokushisa eyiqhwa. Ngesikhathi esifanayo, ukulayisha okuncane kungasetshenziswa ekusebenzeni kwezingxenye eziyisipele kanye noku-oda nokugcinwa kwebhafa ngesivinini esikhulu kanye nendawo enkulu yokugcina impahla.

-

Isixazululo se-Automated miniload AS/RS

I-Miniload AS/RS ingolunye uhlobo lwesixazululo se-racking esizenzakalelayo, okungamasistimu alawulwa ngekhompuyutha okugcina nokukhipha imikhiqizo endaweni yokugcina impahla noma esikhungweni sokusabalalisa. I-AS/RS Systems ayidingi nhlobo umsebenzi wezandla futhi iklanyelwe ukuthi izenzekele ngokuphelele. Amasistimu we-Mini-Load AS/RS angamasistimu amancane futhi ngokuvamile avumela ukukhethwa kwezinto kumathoyizi, amathreyi, noma amabhokisi.

-

I-Vertical Spiral Conveyor Screw System

Ama-Spiral conveyors wuhlobo lwesistimu ezenzakalelayo yokuthi indawo yokugcina impahla ilethe futhi idlulise izimpahla zisuka ohlelweni lokudwengula. Ingasetshenziselwa ukuhlanganisa imikhiqizo isuka kumojula yokukhetha enamazinga amaningi iye emugqeni owodwa wokuthutha wokuthutha. Zingasiza futhi ukuqongelela umkhiqizo ku-spiral ukwandisa isikhathi se-buffer. Kwenziwa ngendlela oyifisayo ukuphatha ngokuphephile umkhiqizo ohlukahlukene, singakusiza ukuthi usebenzise isisombululo esifanele esingabizi kakhulu semisebenzi yakho.

-

Isistimu yokulondoloza ezenzakalelayo enezinto eziwumsebenzi omncane

I-AS/RS yokugcinwa komthwalo omncane yakhiwe nge-high bay racking system, i-othomathikhi ye-stacker crane, isistimu yokuthutha, uhlelo lokulawula indawo yokugcina impahla, uhlelo lokuphatha i-warehouse kanye nemishini yokugcina ehlobene. Ukusetshenziswa kwe-stacker crane ukufaka esikhundleni sendawo yokugcina ngesandla kanye nama-forklift futhi abasebenzi futhi asikho isidingo sokungena endaweni yokugcina impahla, ebona isisombululo esiphelele esizenzakalelayo sokugcina impahla.

-

I-Industrial Warehouse Storage Automatic Spiral Conveyor System

I-Automatic Spiral Conveyor System iwuhlobo olulodwa lwesistimu yokuthutha okuzenzakalelayo esetshenziswa kanye nesistimu yokurakha. Lona umshini wokuthutha ophakamisayo, osetshenziswa kakhulu ekupakishweni, ekwenzeni imithi, ekwenzeni amaphepha, embonini yamakhemikhali, embonini yokudla nezinye izinkambu.Njengohlelo lokuhambisa oluphakamisayo, i-screw conveyor idlale indima enkulu.

-

I-automated pallet shuttle ene-crane stacker

I-automated pallet shuttle ene-crane stacker iwuhlobo lwesistimu yokubeka i-othomathikhi ehlanganisa imishini yokubamba okuzenzakalelayo ne-warehouse rack. Ivumela amakhasimende ukuthi onge izindleko, athuthukise ukusebenza kahle.

-

Uhlelo lwe-ASRS Crane lwePallets

I-Automated Storage and Retrieval Systems yaziwa nangokuthi i-AS/RS inikeza ukuminyana okuphezulu kokulayisha i-pallet, kwandiswe isikhala esiqondile ohlelweni oluphelele lokusebenza lapho uhlelo luhamba ezindaweni ezincane kakhulu futhi ngama-oda wekhwalithi ephezulu. Isistimu ngayinye ye-AS/RS Unit Load yakhelwe ukuba ibe yiphalethi yakho noma omunye umumo omkhulu womthwalo ofakwe esitsheni, kanye nosayizi.

-

Umthwalo omncane we-ASRS wamaTotes namaCarton

Amasistimu we-ASRS amancane ayisixazululo esikahle sokusingatha imithwalo yemisebenzi elula yezinhlobo ezahlukene zamakesi epulasitiki, iziqukathi zepulasitiki namabhokisi, futhi ahlinzeka ngohlelo oluphakeme kakhulu lokukha lokuqoshwa kwempahla. i-miniload system i-automated, ihamba ngokushesha futhi isebenza ngokuphephile, futhi ingahlelwa ngokwezidingo zephrojekthi.

-

I-automatic racking system ene-radio shuttle system

I-Asrs enesistimu ye-shuttle ye-radio ingenye yezinhlobo ze-automatic racking system. Ingagcina izindawo eziningi zephalethi endaweni yokugcina impahla. Uhlelo lwakhiwe nge-stacker crane, i-shuttle, isistimu yokudlulisa enezingqimba, uhlelo lwama-racking, uhlelo lokulawula ukuphathwa kwe-WMS/WCS.